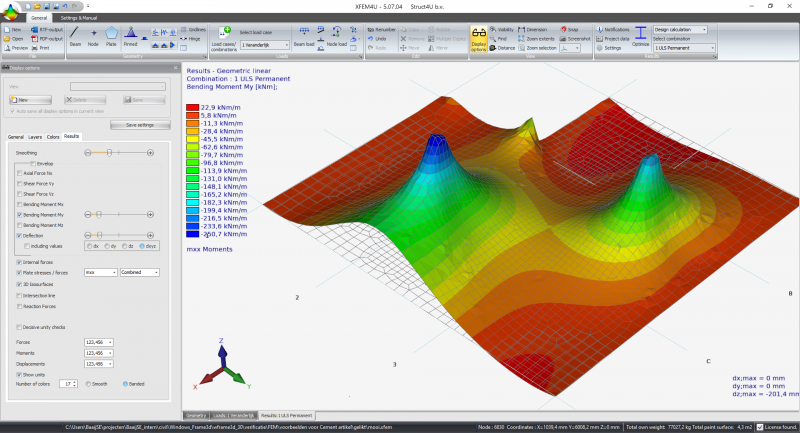

FEM best practices and examples

Preface

FEM-solver

The FEM-solver is written completely in C# with multiple core support. For plates it is geometrically linear. So second order effects are not taken into account. For beams it is geometrically non-linear. So second order effects are taken into account.

Mesh element/theory

The mesh element used with in plates in XFEM4U is a modified Kirchhoff element. It is extended in 2021 by Professor Blaauwendraad. Usually Kirchhoff is less precise regarding the shear force distribution within a plate. In the modified hybrid element this is solved. Therefore it is a extremely robust mesh element with very reliable shear force distribution. For more information check this scientific article about this new element which is completely implemented in XFEM4U.

Mesher

The mesher is using a 4-nodes quadrangle elements because they are more accurate than 3-nodes triangle elements. On a edge there are at least 2 elements with an even number.

Mesh Size

Below we describe a method how to find the right mesh size for your structure. If you make the mesh too dense, internal forces will be higher then reality mainly because of point loads, point and linear supports. In reality they have a curtain area. In the model they are points and therefore infinite stress can occur.

First some basics

- Element size should never be smaller then the plate thickness. Otherwise the theory of Kirchhoff is not correct anymore.

- Element size is at least the smallest span in the structure to expect a correct result.

- Steel plate structures: If you make the mesh size 50% smaller the stress should not increase more then 10-12%.

Workflow within a steel structure

Workflow to find the right mesh size within a steel structure. Especially around areas with point loads/supports, line loads/supports we need to change our mesh size locally.

- Start with a mesh of the platethickness*2.

Plate on Grade

Within XFEM4U there is an option to support a plate on grade(elastic soil). The elastic soil