Documentation XFEM4U: Difference between revisions

| Line 863: | Line 863: | ||

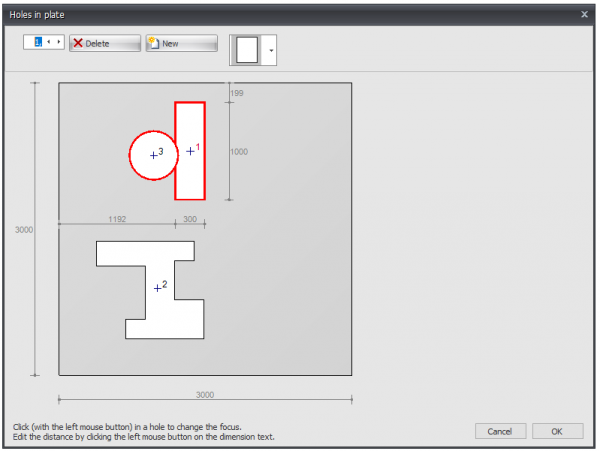

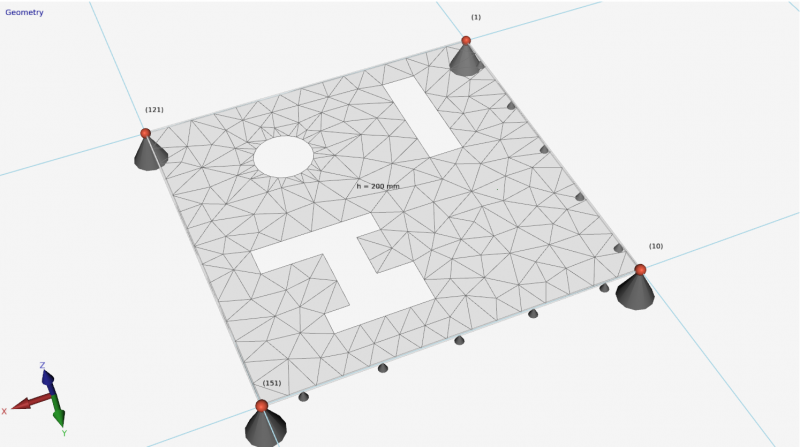

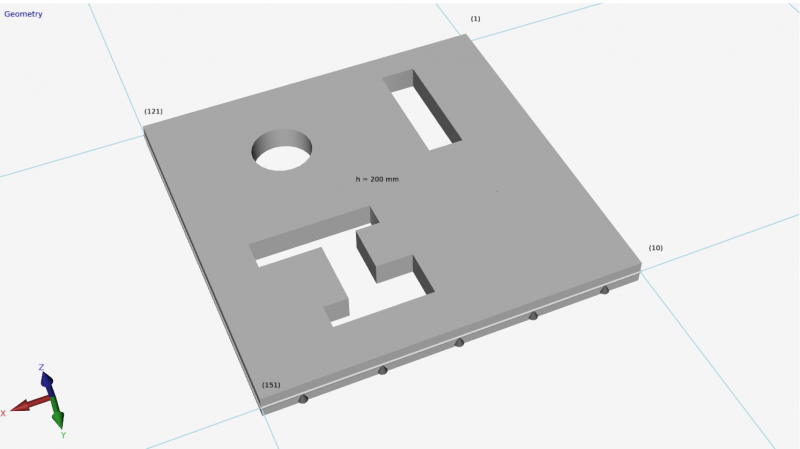

Here you can easily enter holes or openings. You can choose from a large number of basic shapes that are parameterized. | Here you can easily enter holes or openings. You can choose from a large number of basic shapes that are parameterized. | ||

[[File:Holes in plate V2.png|50px|none|]] | |||

The position and dimensions of the hole or opening can be adjusted by clicking on the relevant dimension line. The focus in case of multiple holes can be changed by clicking with the left mouse button in the hole contour. If you hold down the left mouse button and move the mouse, you can move the hole graphically. It checks whether holes overlap or cut through the outer contour. | The position and dimensions of the hole or opening can be adjusted by clicking on the relevant dimension line. The focus in case of multiple holes can be changed by clicking with the left mouse button in the hole contour. If you hold down the left mouse button and move the mouse, you can move the hole graphically. It checks whether holes overlap or cut through the outer contour. | ||

[[File:Holes in plate V3.png|600px|none|]] | |||

Holes in | [[File:Holes in plate V4.png|800px|none|]] | ||

plate | [[File:Holes in plate V5.png|800px|none|]] | ||

=====Plate edge===== | =====Plate edge===== | ||

Revision as of 08:09, 29 July 2022

Introduction

This page contains the documentation of XFEM4U. It is meant as a full description of all functions and possibilities of the program. Other relevant information about XFEM4U can be found in the following links:

Release Notes

Releasenotes of XFEM4U: [link]

Possibilities and limitations

Full list of features of XFEM4U can be found here.

Coordinate System

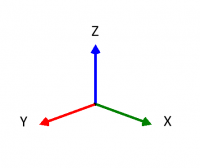

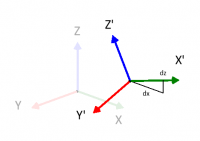

The program knows four clockwise coordinate systems.

Main coordinate system

The location of this global coordinate system is arbitrary. The XY-plane coincides with the plane of the framework. This coordinate system is used for setting the node coordinates, node limitations and node loads. Calculated node deformations and support reactions will be displayed relative to this coordinate system.

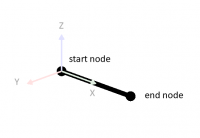

Beam coordinate system

The origin of this coordinate system is always in the beginning of the relevant beam. The XZ-plane coincides with the plane of the framework. The x-axis coincides with the beam-axis.

Node coordinate system

It is possible to use a local (node-) coordinate system. The origin lies in the relevant node. The direction of the x-axis is determined by assigning a relative dx and dz coming from the relevant node ( see the figure above). Local coordinate systems can be used to calculate node limitations ( support reactions and restrains ), node loads and/or node deformations in an arbitrary direction.

Plate coordinate system

The planar plane of the plate is the local XY-plane. If the plate is drawn clockwise then the Z-axe is positive.

The in- and output data will be displayed with regard to the above explained coordinate system.

- A force in the direction of the positive x- or z- axis is considered positive.

- A moment rotating from the positive x-axis to the positive z-axis (according to the cork-screw rule) is positive.

- A moment opposite to the 'clockwise' rotation is positive.

Input

For navigating in your 3d model, 2 common methods are supported. You can set which one you want to use. Tab Settings & Manual > Settings > Navigate tab See Navigating

1. Method as in Autodesk Revit (default)

- 'Zooming in and out: Use the mouse wheel.

- 'Pan: Press the mouse wheel and drag.

- Orbit: Press the mouse wheel and SHIFT' key together and drag.

2. Method as in Tekla structures

- Zoom in and out": Use the mouse wheel.

- Pan": Press the mouse wheel and drag.

- Orbit": Press the mouse wheel and CTRL key together and drag.

XFEM4U also supports the use of a 3d mouse (from e.g. 3D Connection ) which makes working even easier and faster.

Geometry

In this section we have a look at all the geometry functions within XFEM4U

Beams

Preface

In the graphical screen beams can be added very easy by drawing them. Select this item in the function bar. Beams are drawn as a 'polyline' just as you know it from AutoCAD.The begin node from a following beam is the end node of the last drawn beam.

It is possible, but not necessary, to draw nodes before you insert the beams. You can also start with drawing the beams, in this way the nodes will be inserted automatically.

When you draw your first beam, the dialog box shown below appears. In this box you can, among other things, insert the beam connections and the profile of the beam. Use the escape-key or click the right mouse button to end the drawing of the beams.

As you are drawing a beam, help lines (horizontal and vertical) will appear connected to the previous inserted nodes. Often the node, to which you want to draw the beam, has the same x- or y- or z-value as the previous one. In this way it is easy to insert nodes. Obviously you can adapt the coordinates afterwards numerically or by moving the node.

While drawing a new beam, a dimension line parallel to the beam in one of the main directions x,y or z will appear. You can, just as you know it from AutoCad, immediately insert the distances numerically by entering the value / values from your keyboard. There are 3 possibilities for drawing a beam:

1. Drawing a beam with a known length in one of the main directions.

The value will appear in the dimension line. Here you can type in the distance. By the use of the enter-key the input is closed and the beam with that length will be added.

2. Drawing a beam using relative Cartesian coordinates (dx, dy, dz).

First you enter the distance in x-direction. The value will appear in the dimension line. Thereafter you type a semicolon ";" and the distance in y-direction. The value will appear in a second input field. Next you type a semicolon ";" and the distance in z-direction. The value will appear in a third input field. By the use of the enter-key the input is closed and the beam is added.

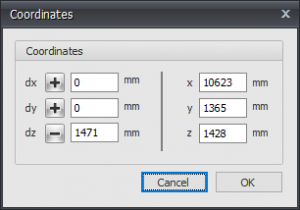

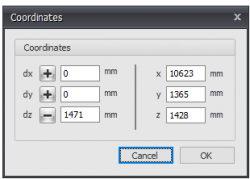

3. Input of relative cartesian coordinates (dx, dy, dz) or absolute cartesian coordinates (x, y, z).

Press the space key and the dialog box below appears. Here you can enter relative coordinates or absolute coordinates directly.

In this way, you can quickly insert your construction.

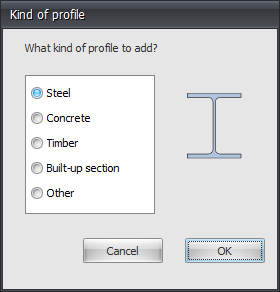

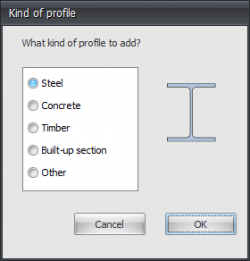

When you draw a beam for the first time, a profile needs to be chosen / inserted. There is asked what kind of profile you want to add. Also when you insert a new profile, there is asked which kind of profile you want to add.

Subsequently the following dialog box of the profiles is shown. See Profiles

Changing a beam

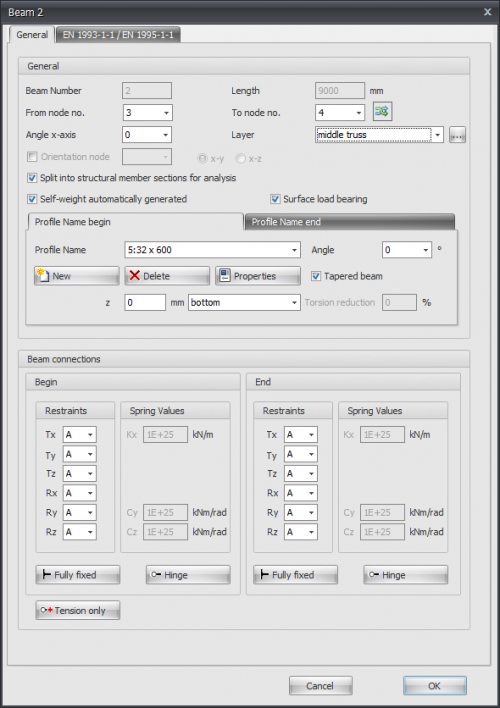

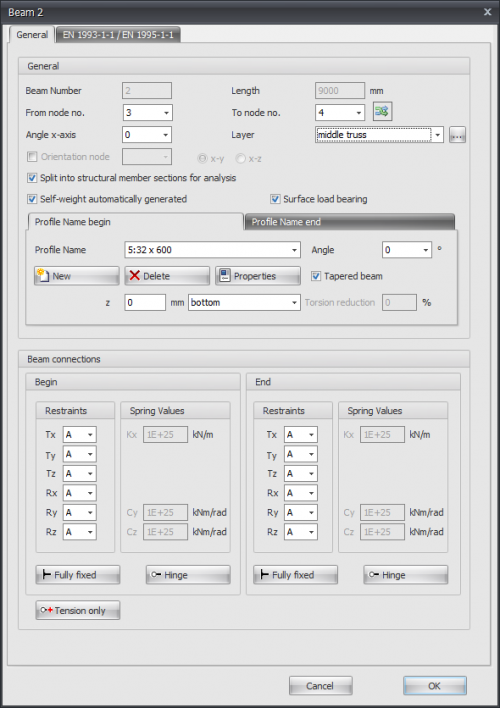

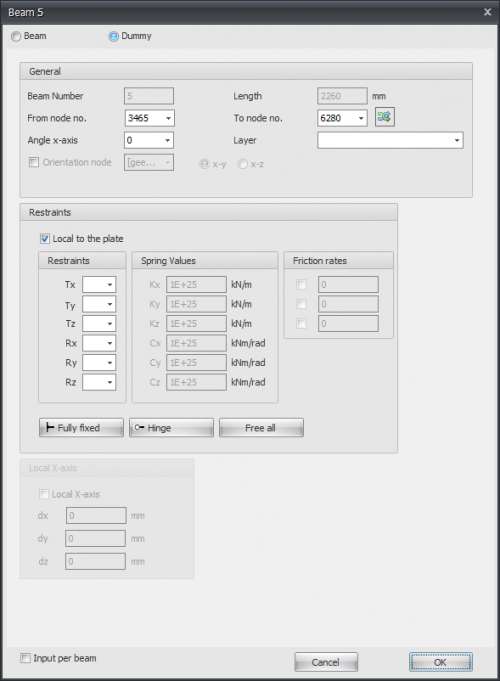

Changing a beam is possible by clicking on the beam with the left mouse button, and subsequently choose for properties by clicking with the right mouse button. There is a more easy way, namely a double click on the beam. Consequently the following dialog box will be opened.

Beamproperties: General

Beam number

The number of the beam.

Length

The length of the beam in mm.

From node no.

The number of the begin node.

To node no.

The number of the end node.

flip

By the use of this function, you can turn around the beam orientation. The begin- and end node will be switched.

Angle x-axis

The angle in which the local coordinate system can rotate around the x-axis.

The clockwise direction is positive.

Layer

Beams can optionally be drawn in layers. This corresponds to the functionality of AutoCAD. The layers can be set visible or invisible. (on/off). You can adapt the names of the layers. See Display options

Orientation node

The number of the orientation node. This is a node in the local x-y plane or in the x-z plane.

Split into structural member sections for analysis

Setting whether, for the determination of the force distribution (framework calculation), the beam has to be split in in partial beams when nodes are found on the beam. This function is enabled by default.

Self-weight automatically generated.

Setting whether the dead weight of the beam needs to be generated. This function is enabled by default. See Calculation settings

Surface load bearing

Setting whether the beam carries the surface load or not. See Surface loads

Profile Name

Here you choose the profile type

Angle

The angle of the profile. That is the angle relative to the local coordinate system. Normally this is zero degrees. When you want to for example enter the column rotated (so loaded at it's weak axis) you fill in 90 degrees

New Delete Properties

You can also add new profiles and delete profiles. Choose for Properties when you want to adapt the profile data and/or want to select another standard profile type from the profile database.

With every new profile, there is asked what kind of profile you want to add.

Tapered beam

You can optionally enter a tapered beam (Non-prismatic beam). The tab "Profile end" is activated. Here you can enter the 2nd profile at the end of the beam. Attention! The basic shape of the profile section (H-, U-, L-shape, etc.) must match that of the profile at the beginning of the beam.

For calculation background. See Tapered beam

z

With this the profile is orientated relative to the schematic line. ( The schematic line is the line from the begin node to the end node) z is the distance in the local z-direction between the schematic line and the reference line of the profile. The reference line of the profile is showed in the middle by default, but can be set at the top, middle or bottom.

Torsion reduction

Percentage by which the torsion stiffness of the beam is reduced. Specifically for concrete beam grids, it is allowed to reduce the torsion stiffness in case of compatibility torsion. Thereby the occurring torsion moment is lower, and less torsion reinforcement is needed. (stirrups and longitudinal reinforcement)

Beam connection begin and end

Here you enter how the beam is connected at the begin node and at the end node. There are multiple options.

You can make use of the most common / standard connections:

Fully fixed

Tx=A(Absolute), Ty=A, Tz=A, Rx=A, Ry=A, Rz=A. (That is the standard setting)

Hinge

Tx=A, Ty=A, Tz=A. There is no transfer possible between moments, only shear force and normal force.

Tension only

This works the same as a hinge support, the only difference is that tensile forces (positive normal forces) can be transferred.

Springer connection

You can also add a beam with a springer connection. Tx=S(Spring), Ry=S en/of Rz=S. You also need to insert the spring constant Kx, Cy and/or Cz in kN/m resp. kNm/rad

Input per beam

This gives you the possibility to adapt the input for every new beam.

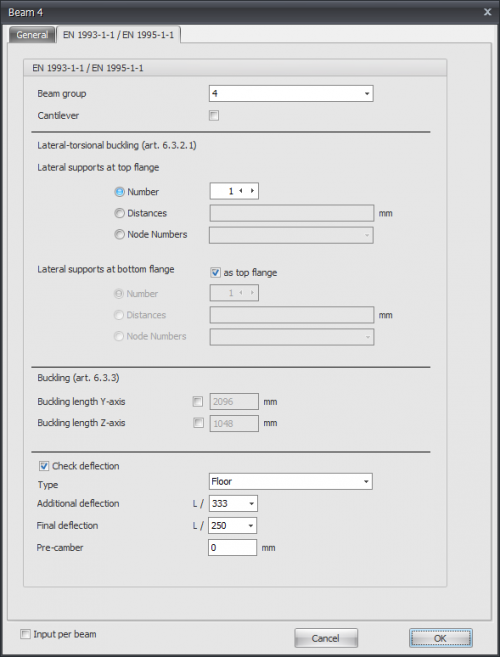

Beamproperties: Eurocode

EN 1993-1-1 / EN 1995-1-1

Specifically and only for the check according to Eurocode 3: EN 1993-1-1 respectively Eurocode 5: NEN-EN 1995-1-1data can be inserted.

Beam group

Specifically and only for the lateral-torsional buckling resistance check a beam group can be inserted here. XFEM4U automatically detects for which beams this qualifies. Only the beams which are connected by a fully fixed connection to this particular beam and have the same profile will be showed. You can select which beams should be taken into account. For this group you subsequently enter the length between the lateral restraints and the buckling length out of plane.

Lateral torsional buckling

Amount of lateral supports / distances between lateral supports

This is only relevant for the check of lateral torsional buckling. You can enter the lateral supports for the top and the bottom flange.

There are 3 options:

1. Number: The amount of lateral supports. That are the extra (lateral supports) between the supports distributed over the length of the beam(group)

2. Distances: The lengths between the lateral restraints from the beginning of the beam (group). The syntax is length1 length2 amountxlenght3.. etc.

For example 3000 3x2200 2800

3. Node numbers: Selecting the node numbers which are in the beam group.

Buckling lengths Y-axis and Z-axis

The check according to Eurocode 3: EN 1993-1-1 is based on a geometric non linear force distribution. This means that the buckling of the beams in the plane of the frameworks is provided implicit in the force distribution. For every load combination the internal stability is determined iteratively. By default the buckling length around the y-axis is equal to the beam length. The buckling length around the z-axis is equal to the biggest lateral torsional buckling length. You can also enter different values for both the buckling lengths. See also Buckling.

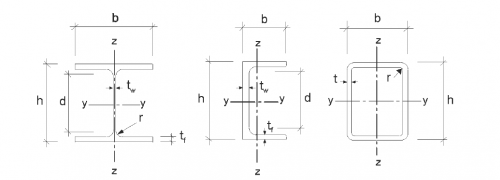

Note: Regardless of whether the profile is rotated with respect to the local coordinate system, the Y axis is the strong axis and the Z axis is the weak axis analogous to the Eurocode. (See below.) In all checks, all beam forces are transformed to this coordinate system.

Check deflection

Setting if deflection has to be checked.

Type

This influences the requirement of additional deflection.

Additional deflection

Requirement of additional deflection.

Final deflection

Requirements of final deflection.

Pre-camber

The size of pre-camber in mm.

Beamproperties: Dummy

Specifically for plates, it is possible to enter dummy beams. Arithmetically, a dummy beam is taken into account with small bending stiffness.

Line Loads: With dummy beams, any line loads on a plate can be taken into account.

Line supports: Dummy beams can be supported by.

Beam number

The number of the beam.

Length

The length of the beam in mm.

From node no.

The number of the begin node.

To node no.

The number of the end node.

flip

By the use of this function, you can turn around the beam orientation. The begin- and end node will be switched.

Angle x-axis

The angle in which the local coordinate system can rotate around the x-axis.

The clockwise direction is positive.

Layer

Beams can optionally be drawn in layers. This corresponds to the functionality of AutoCAD. The layers can be set visible or invisible. (on/off). You can adapt the names of the layers. See Display options

Orientation node

The number of the orientation node. This is a node in the local x-y plane or in the x-z plane.

Line supports

Indication/ Description

' ' free - no limitation

'A' Fully limited (Absolute)

'P' Limited for a Positive reaction force; free for a negative reaction force

'N' Limited for a Negative reaction force; free for a positive reaction force

'S' Springer (Spring); spring value needs to be inserted

Local to the plate

Setting whether the supports are to be introduced in relation to the local axle system of the plate.

Supports / Restraints

Here you enter how the beam is supported. There are many possibilities.

You can use the most common / standard supports:

- Fully fixed Tx=A(Absolute), Ty=A, Tz=A, Rx=A, Ry=A, Rz=A. (That is the default setting)

- Hinged Tx=A, Ty=A, Tz=A. No moments can be transmitted, only transverse and normal forces.

Spring support

You can also enter a spring support. Tx=S(Spring), Ry=S and/or Rz=S. You also give the spring value Kx, Cy and/or Cz in kN/m or kNm/rad.

Local x-axis see Local coordinate system

Input per beam

This gives you the possibility to adapt the input for every new beam.

Profiles

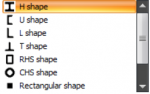

The first time you draw a beam, a profile needs to be chosen / inserted. There is asked what kind of profile you want to add. Also if you want to enter a new profile, there is asked what kind of profile you want to insert.

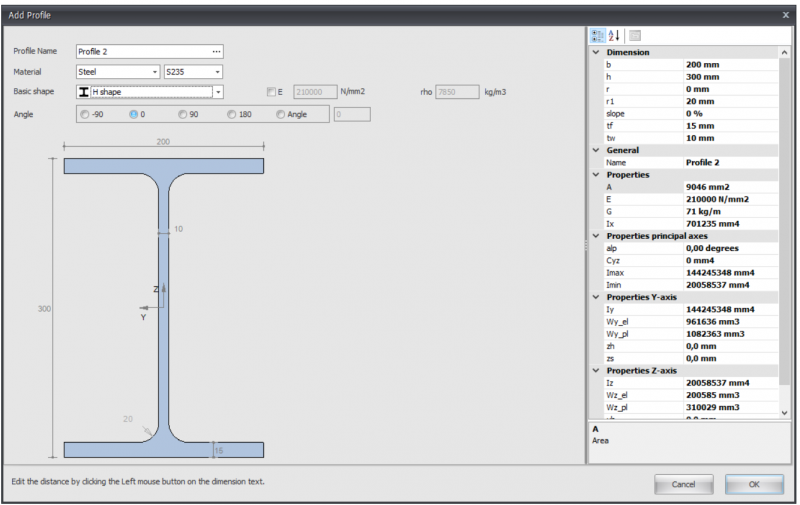

Steel

Remark:

You can adapt all profile dimensions by clicking on the concerning values in the dimension lines.

Profile name:

You can enter the profile name here, or select a profile from the database. You can also directly type IPE160, HEA200 or HE200A here.

Do you want to enter a common steel profile from the database, click on the 3 dots... at the right side of the input field.

After you selected a basic shape, you can subsequently adapt all the profile dimensions by clicking on the concerning numbers in the dimension line. You can also adapt the profile dimensions of the standard profiles by the use of this method.

E

The elasticity modulus, which is adaptable.

Angle

You can rotate the profile among an angle

Concrete

Cross sectional shape

You can choose from a big amount of cross sectional shapes. When you chose a shape, you can subsequently adapt the profile dimensions by clicking on the concerning values in the dimension lines.

Concrete top layer

Setting whether you want to insert a in-situ concrete top layer with a different concrete grade

Prefab

Setting whether you want to use prefab concrete

Concrete grade

The concrete grade

Steel grade

The steel grade of the basic and additional reinforcement.

Creep coefficient

The creep coefficient of concrete. By this coefficient the effective creep coefficient is calculated according to EN 1992-1-1 art. 5.8.4.

You can insert the creep coefficient yourself or you can have it calculated. See Creep. When the creep coefficient is calculated, a detailed calculation according to EN 1992-1-1 B.1 is displayed in the output as well.

Granule diameter

The nominal granule diameter of concrete

Granule diameter

The nominal granule diameter of concrete

h

The height of the concrete cross section in mm

b

The width of the concrete cross section in mm

h concrete layer

The height of the in-situ concrete top layer in mm

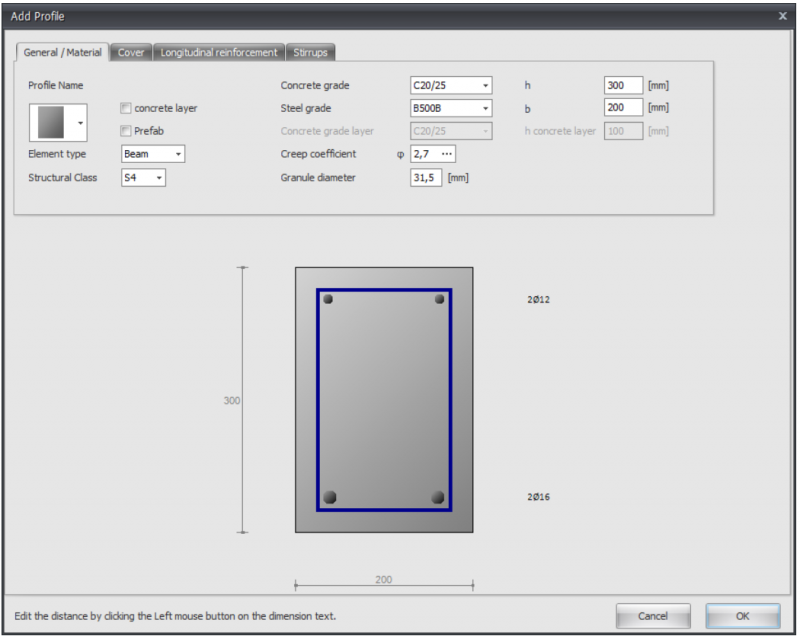

Environmental class

The environmental or exposure class is used for the determination of the required cover. See Exposure classes

Concrete surface

Can be checked, can not be checked or finished

delta_Cdev

Execution tolerance of the concrete cover in mm

Cover

Concrete cover top / bottom in mm

Side cover

Side cover left / right in mm

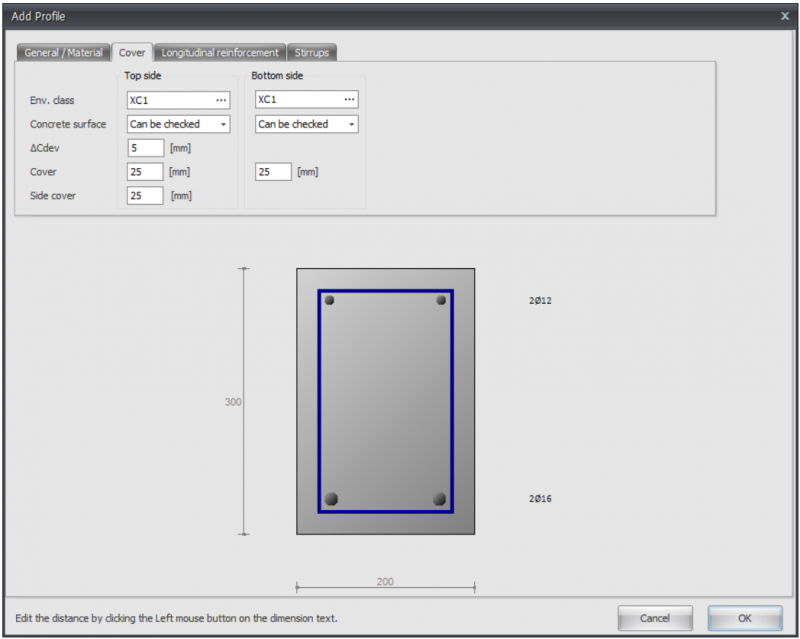

Basic reinforcement

Basic reinforcement top/bottom

Syntax 1: <amount>x<diameter> [+<amount>x<diameter>...]

Syntax 2: <diameter>-<ctc distance> [+<diameter>-<ctc distance>...]

Syntax 3: <mm2> [ / <diameter>]

2nd layer

Basic reinforcement top / bottom in the second layer

Additional reinforcement diameters

The diameters by which the additional reinforcement is designed

Layers

When designing a floor, the option if the basis reinforcement is in the first or in the second layer

Transverse reinforcement

When designing a floor, the diameter of the transverse reinforcement

Concrete trench

Concrete trench in mm

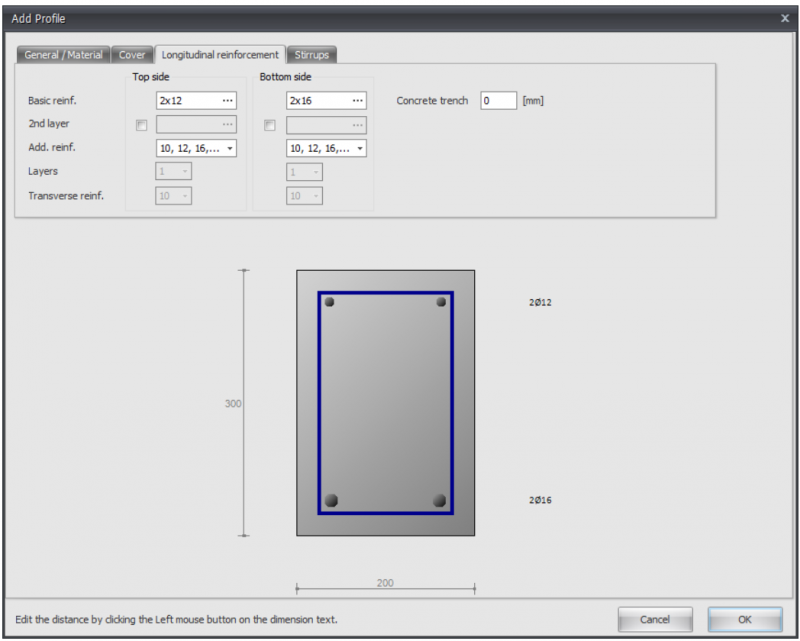

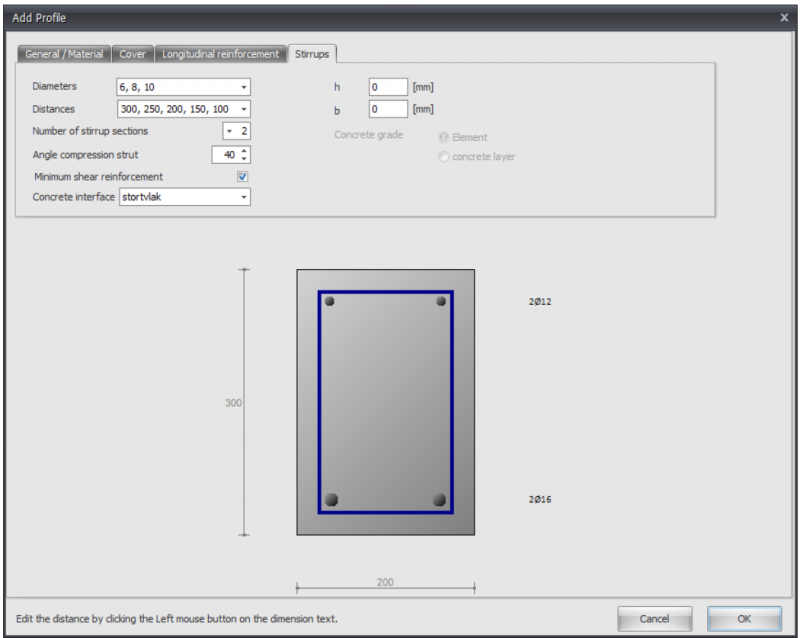

Diameters

Stirrup diameters

Distances

Stirrup distances

Number of stirrup sections

The number of stirrup sections. For shear force this is normally 2.

Angle compression strut

Angle compression strut in degrees

Minimum shear reinforcement

Setting whether the minimum shear reinforcement should be taken in to account.

Concrete interface

In the case of a in-situ concrete top layer, the pouring surface can be entered here.

h

Height of the concrete cross section for the shear force calculation in mm.

b

Width of the concrete cross section for the shear force calculation in mm.

Concrete grade

In case of a in-situ concrete top layer: Concrete grade that needs to be used for the shear force calculation.

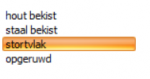

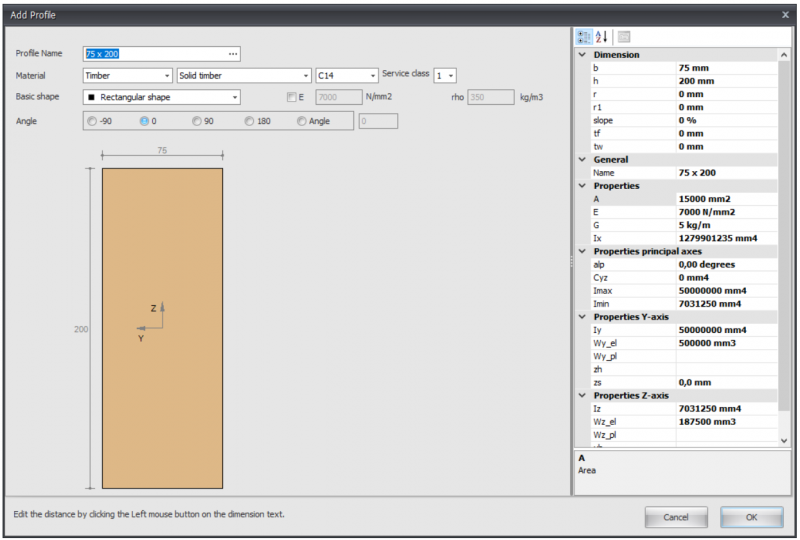

Timber

Remark:

You can change the profile sizes by clicking on the concerning values in the dimension line.

Profile name

Enter the profile name or select a profile from the existing database. You can also directly type 75 x 200 of 75 x 225

When you want to enter a known timber profile from the database, click on the 3 dots... on the right side of the input field.

Material

Timber

Type of timber

Timber class

Climate class

Basic shape

You can choose from an amount of basic shapes. In this way you can make the profile yourself.

After you selected a basic shape, you can subsequently adapt all the profile sizes by clicking on the concerning values in the dimension line. You can also can adapt the profile sizes of the standard profiles in this way.

E

The elasticity modulus which is adaptable

Angle

You can rotate the profile among an angle

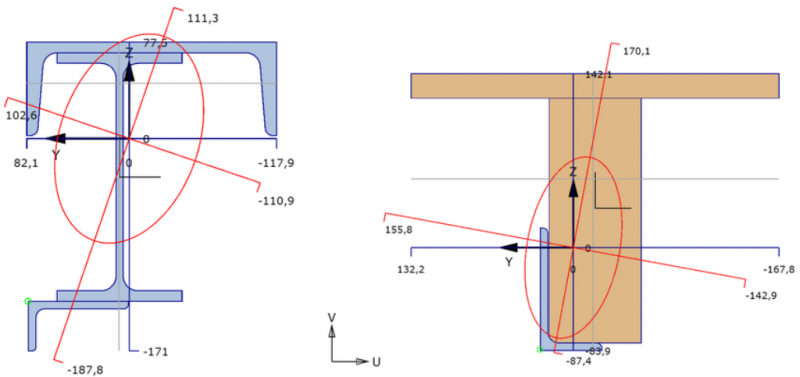

Build-up selection

With this module you can built up any section.

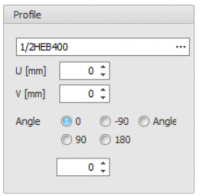

Input

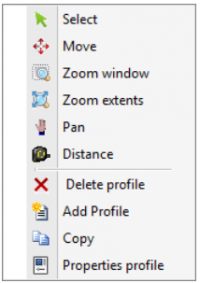

You can Add, Copy and Delete any profiles here. Using Properties you can change your profile or alter the profile dimensions.

Profile name

Enter the profile name or select from our profile database.

Special input:

- Half H syntax: "1/2 profile name [ - min dimension ]" Example: 1/2IPE300 or 1/2HE650B-5

- Rectangular: syntax: "S width x height" of "F width x height" Example: S200x12

- Hole: syntax: "G width x height" of "H width x height" Example: H50x2

- Round: syntax: "R diameter Example: R50

- Tube(segment): syntax: "R diameter x thickness [ / hoek1 / hoek2 ] " Example: R500x12 or R500x12/0/180

- Trangle: syntax: "D width x height" of "T width x height" Example: T50x60

U

Coordinate u in mm

V

Coordinate v in mm

Angle

Angle in degrees

Graphical input

Graphical view of the built up section, with:

- cross section of all profiles use. The focused section is displayed with another color.

- coordinate system

- centroid

- principal axis

- distances from centroid to all largest dimension

- display of radius of gyration

- display of plastic neutral axis

Mouse right click context menu

Menu

Slabs/Plates

General

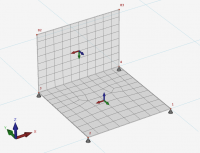

In the graphical screen slabs can be added very easy by drawing them. Select this item in the function bar.

![]()

Plate egdes are drawn as a 'polyline' just as you know it from AutoCAD.The begin node from a following beam is the end node of the last drawn plate edge.

It is possible, but not necessary, to draw nodes before you insert the plates.

You can also start with drawing the plate edges, in this way the nodes will be inserted automatically.

When you draw your first plate edge, the dialog box shown below appears. In this box you can, among other things, insert the material data of the slab. Use the escape-key or click the right mouse button to end the drawing of the plate edges.

As you are drawing a plate edge, help lines (horizontal and vertical) will appear connected to the previous inserted nodes. Often the node, to which you want to draw the beam, has the same x- or y- or z-value as the previous one. In this way it is easy to insert nodes. Obviously you can adapt the coordinates afterwards numerically or by moving the node.

While drawing a new plate edge, a dimension line parallel to the plate edge in one of the main directions x,y or z will appear. You can, just as you know it from AutoCad, immediately insert the distances numerically by entering the value / values from your keyboard. There are 3 possibilities for drawing a plate edge:

1. Drawing a plate edge with a known length in one of the main directions.

The value will appear in the dimension line. Here you can type in the distance. By the use of the enter-key the input is closed and the plate edge with that length will be added.

2. Drawing a plate edge using relative Cartesian coordinates (dx, dy, dz).

First you enter the distance in x-direction. The value will appear in the dimension line. Thereafter you type a semicolon ";" and the distance in y-direction. The value will appear in a second input field. Next you type a semicolon ";" and the distance in z-direction. The value will appear in a third input field. By the use of the enter-key the input is closed and the plate edge is added.

3. Input of relative cartesian coordinates (dx, dy, dz) or absolute cartesian coordinates (x, y, z).

Press the space key and the dialog box below appears. Here you can enter relative coordinates or absolute coordinates directly.

In this way, you can quickly insert your slab/plate.

The plate can be supported in different ways. By Nodes and/or Plate edge.

You can enter Plate loads and/or Node loads.

Reinforcement

General

Steel grade

The steel grade of the basic and additional reinforcement.

Creep coefficient

The creep coefficient of concrete. By this coefficient the effective creep coefficient is calculated according to EN 1992-1-1 art. 5.8.4.

You can insert the creep coefficient yourself or you can have it calculated. See Creep. When the creep coefficient is calculated, a detailed calculation according to EN 1992-1-1 B.1 is displayed in the output as well.

Granule diameter

The nominal granule diameter of concrete.

Cover

Environmental class

The environmental or exposure class is used for the determination of the required cover. See Exposure classes

Concrete surface

Can be checked, can not be checked or finished

delta_Cdev

Execution tolerance of the concrete cover in mm

Cover

Concrete cover top / bottom in mm

Reinforcement

Reinforcement in X- and Y-direction

Basic reinforcement top/bottom

Syntax 1: <amount>x<diameter> [+<amount>x<diameter>...]

Syntax 2: <diameter>-<ctc distance> [+<diameter>-<ctc distance>...]

Syntax 3: <mm2> [ / <diameter>]

Additional reinforcement diameters

The diameters by which the additional reinforcement is designed

Layers

Setting which reinforcement is in the first layer

Angle compression strut

Shear reinforcement: Angle compression strut in degrees

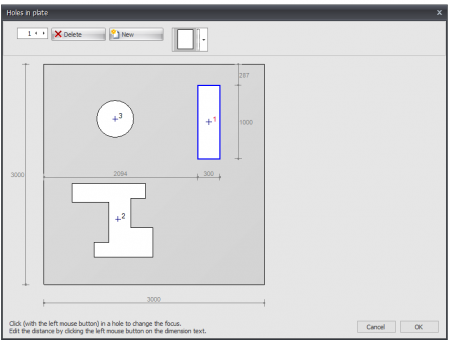

Holes in plate

Here you can easily enter holes or openings. You can choose from a large number of basic shapes that are parameterized.

The position and dimensions of the hole or opening can be adjusted by clicking on the relevant dimension line. The focus in case of multiple holes can be changed by clicking with the left mouse button in the hole contour. If you hold down the left mouse button and move the mouse, you can move the hole graphically. It checks whether holes overlap or cut through the outer contour.